5 Signs You Need a New Concrete Floor Coating

5 Signs It’s Time For a New Concrete Floor Coating

Concrete floors are built to last and will last even longer with the proper coating. A protective coating prevents damage to the concrete, blocking the moisture or chemicals that would have otherwise gotten to the floor.

But how do you know it is time to coat? When does a repair job in a small section do the trick, and when is it time to recoat the whole floor? Here are the top five signs that you may need a new floor coating.

1. Cracks Are Appearing

As your concrete expands and contracts as your foundation moves, the weight on the floor and the season’s temperature, the polyurea coating moves with it. It has the elasticity that will move with your floor.

Once your coating starts to crack, the concrete becomes more vulnerable to damage from debris, salt, spills and moisture. Call a professional about getting a polyurea coating to repair the cracks before they get extensive.

2. Your Floor Is Uneven

An uneven floor can happen to any part of your house. As the years go by, construction errors, external movements and wear and tear can come into play. Some common reasons why floors become uneven over time are:

- Extra moisture: If there’s a leak in your pipes or the water main, the excess moisture can cause the soil to shift, creating uneven floors in your house.

- Ground movement: In addition to moisture, tree roots expanding into the area or nearby construction can cause the soil under your garage to move.

- Errors in construction: Construction workers need to compact the ground before construction. If the contractor rushed through this step or did it during wet weather, the soil might shift later. Undersized foundations are another possible cause.

- Pressure: Constant weight or traffic on top of the floor can press down and cause an uneven surface.

A coat of polyurea could even out a mildly uneven surface. You’ll need more significant repairs if the floor is sagging or visually sinking.

3. Moisture and Water Collection

While the foundation and infrastructure block moisture from below, your polyurea coating stops moisture from reaching the concrete floor from above.

High humidity and trapped moisture can lead to corrosion that damages concrete. Eventually, the concrete will become brittle and crumbly. If a spot in your garage is constantly wet, you must find the source of the moisture.

Possible explanations could be:

- A leaky pipe.

- Water dripping from the roof.

- An unsealed shower or water source.

4. Peeling and Bubbling

There are two reasons why your coat could be peeling and bubbling:

- It is an out-of-date coating that has gotten old: Modern coatings, such as polyurea concrete coating, cannot flake and peel. Replacing your old coat with a more durable polyurea coating will help restore your floor’s aesthetic. Once you have determined there is no water leakage, you can remove the old coating. Then recoat in a modern version that will seal your concrete. This is a tenacious project and should be done by a professional.

- Moisture is rising from underneath in the concrete: A polyurea coating helps block water vapor that can rise from beneath the concrete. Bubbling or peeling can be signs that your current coat is no longer trapping that moisture. In this case, you may need to replace your existing floor and add a vapor barrier beneath.

5. Discoloration

Whether you need to repair a section or replace the entire coating will depend on what caused the discoloration. You can typically determine the cause based on the color:

- Dark spots: If you’ve noticed dark spots or stains on your floor, moisture and spilled chemicals are the most likely causes. Concrete floors in garages or workspaces have a higher chance of exposure to grease and chemicals. A professional can clear the spots and recoat those sections.

- Widespread yellow tint: Older coatings turn yellow over time due to exposure to ultraviolet (UV) light. For UV discoloration, it is better to remove the entire coat and apply a new floor coating like a polyurea layer. Polyurea is resistant to UV rays and will not turn yellow.

The Benefits of Applying a New Polyurea Floor Coating

A new polyurea floor coating is an excellent choice for a new concrete floor finish. You can enjoy numerous benefits from a fresh polyurea coat, including the following:

Increased Safety

Your garage floor faces exposure to lots of dirt, bacteria and dust. Everything that spills or drops winds up on the floor and can become a hazard if you don’t clean it quickly. Polyurea is resistant to microbiological contamination and bacteria. Warehouses, hospitals, restaurants and factories use polyurea to aid in their hygiene. Here are some other ways it increases safety:

- It’s resistant to water, dust and dirt, making it easy to clean.

- Its slip-resistant surface makes it safer for people to walk on it.

- The coating can repair mildly uneven floors, helping to prevent accidents.

Durability and Visual Appeal

Polyurea is durable and provides a coating for concrete floors that’s four times stronger than epoxy. It is resistant to a long list, including the following:

- Stains

- Moisture

- Bacteria

- Most chemicals

It rises above other options with its added advantage of being elastic and UV-resistant. The result is a shine that brings out any tints, colors or textures in the concrete design. It gives the floor a professional, sophisticated gloss.

Quick Installation and Easy Maintenance

While recoating a garage floor might sound like a large, time-consuming job, professionals can do it in just a few hours. Polyurea only takes 24 hours to cure fully and is safe to walk on after 12 hours. You can drive your car in and have your garage back to normal just one day after you have it coated.

A polyurea coating also makes your floor super easy to clean. Its resistance to dirt makes it a breeze to sweep everything up, and you can wipe up spills with a clean cloth. It is also skid resistant, so your tires don’t leave a mark.

Revitalize Your Garage Floor With a New Polyurea Coating

Polyurea has a short curing time from mixing to setting, so it’s always best to have professionals apply the coating. You can trust BlackHawk Garage Door to apply your beautiful new concrete floor coat efficiently. We have installed thousands of polyurea coatings and can complete your installation in one day.

We offer our clients free and honest estimates for their floor coatings. Chat with our experienced team about the warranties we offer. Contact us today to learn more!

How to Protect Your Garage Floor

No matter how you use your garage, whether to store your vehicles, keep extra belongings or use as a space for activities, you’ll likely notice some wear and tear on the floor over time. Signs like tire marks, oil stains and moisture damage can all be tells that you need to increase your garage floor protection.

Below, we explore why garage floor protective coating matters and how you can properly protect your garage’s flooring for years to come.

Why It’s Important to Protect Your Garage Floor

Protecting your garage floor increases its longevity and durability. If you use your garage frequently, it’s much more likely that stains, cracks and other types of damage will occur. Therefore, when you maintain your concrete floor and protect its surface, you can avoid cracks, improve protection against moisture damage and create a surface that’s easier to clean.

Maintaining your garage floor will also increase your garage’s safety, as you reduce the chances of people falling on damaged floors. Ensuring your garage floor is even and has a protective coating will decrease the risk to you and your loved ones. This level of protection is especially crucial in the winter — garage floor winter protection guards against salt, snow and other elements that might track into your garage.

How to Protect Your Concrete Garage Floor

Applying a sealant can protect your concrete floor from elements that fall or spill on top of it. Before you apply a sealant, you must hire a professional to inspect the underlying concrete. It’s crucial to address any signs of moisture or disintegration before applying a protective coating. It’s important to open the pores of the concrete before applying protective coating using a diamond grind sander. This allows the sealant to seep into the even layers of the concrete.

Once your floor is ready, you can start looking at options to protect it, such as:

- Epoxy coating

- Sealants

- Polyurethane sealant

- Polyurea

What About Garage Floor Tiles?

While garage floor tiles might look great on top of your concrete floor, garage floor tiles don’t protect your floor from degrading, stains or moisture. However, tiles might be a good option if you don’t use your garage often.

This option is usually rigid or semi-rigid plastic or wood. The tiles interlock, creating a slightly raised platform for your vehicle. The plastic options include ones made from PCS or polypropylene plastic, and wooden choices are made from composite and have tongue-in-groove edges.

Options for Garage Flooring Sealers

All garage floor sealants are divided into two categories — penetrating and topical sealers. Here’s a quick look at their differences:

Penetrating Sealers

These sealers react with the foundation of the floor and create a hard floor finish. Also known as non-film forming sealers, penetrating sealers still maintain a slight wet slip resistance of the original concrete floor.

The disadvantage is that they’re not waterproof or stainproof so if your end-goal is protecting and lengthening the life of your concrete, this is not a good choice.

There are several types of penetrating sealants on the market, but the two main ones are:

- Acrylic concrete sealant: This sealant offers a thin layer that can be tinted with a color. Acrylic sealants offer mild to moderate protection from oil, spills and stains. These sealants are ultraviolet stable and won’t discolor in the sun.

- Silicone sealant: This sealant provides good general protection at a low cost. It offers many benefits compared to other penetrating sealants but not as much protection as a topical option.

Topical Sealers

Protective topical sealants sit on top of the concrete and only slightly penetrate the material below. These are also known as film-forming sealants. They’re the most common type of sealant used in garages, as they’re easy to clean and waterproof. Usually, topical sealants are non-breathable.

You can get a range of colors or decorative options for this sealant or leave it clear. They offer more in terms of being stainproof and give a higher performance, longer life span and slip resistance.

What Is Epoxy Coating?

Epoxy coatings come in several colors, designs and textures, but their base is a synthetic polymer. This coating creates a robust, plastic-like layer that protects your floor from spills and water. During the curing of the epoxy coat, the solvent goes through a process of evaporation, leaving a hard, slippery finish behind.

There’s a product called epoxy paint, which is one part latex paint mixed with a small amount of epoxy. However, the paint is just a finish, not a protective layer, and it shouldn’t be confused with epoxy coating.

Some disadvantages of using epoxy coating are:

- Epoxy is a thermosetting resin that coats the floor, but doesn’t withstand the elasticity you need as your floor foundation settles.

- Epoxy cannot withstand the temperatures of Minnesota and Wisconsin winters and within a few years may encounter pitting, chipping and splitting.

- Epoxy is not UV resistant. Color will fade and yellow with exposure to the sun.

- Epoxy never fully cures. It perpetually hardens and the coating becomes brittle.

What Is Polyurethane Sealant?

Polyurethane sealer is a high-performance coating that’s a step up from epoxy, as it’s more abrasion and scratch resistant, wears longer and offers better stain resistance. Unlike epoxy, this sealant is ultraviolet stable and won’t tint yellow with age.

However, polyurethane doesn’t stick well to concrete on its own. In the past, professionals would use epoxy as a first coat and then apply this sealant to seal the epoxy over the concrete. Polyurea is a sub-category of traditional polyurethane that offers the best of both worlds. It’s ultraviolet stable, like polyurethane, and sticks to concrete like epoxy.

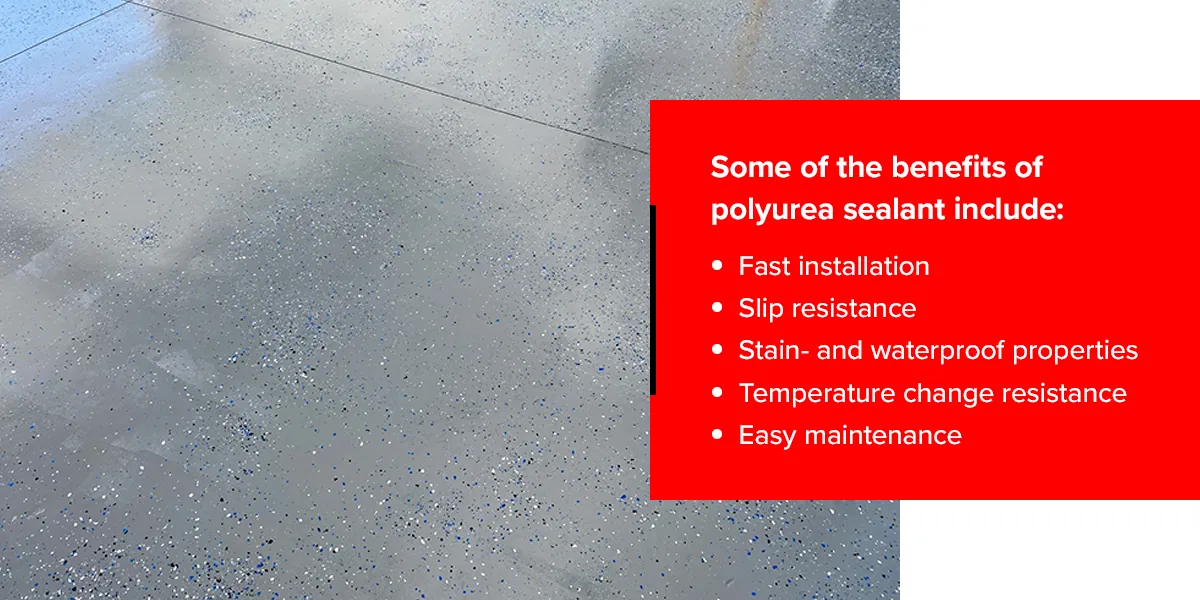

Some of the benefits of polyurea sealant include:

- Fast installation

- Slip resistance

- Stain- and waterproof properties

- Temperature change resistance

- Easy maintenance

- UV stable, will not fade

- 100% Antibacterial

- Polyurea has the flexibility to expand with your floor’s foundation preventing peeling, chipping or flaking.

It’s recommended that a professional installs your polyurea floor coating, as once it’s mixed, the chemicals harden quickly.

What to Consider Before Choosing a Garage Floor Protection Option

Each garage is different in terms of how homeowners use them. Therefore, you need to consider three factors when considering the best option for protective flooring for your garage:

- Durability: Is this a high-traffic space? What’s the size of your car? Is your climate wet and cold? Do you need it to be stain-resistant?

- Ease of installation: Some sealants take up to 24 hours to dry. Others take several days or much shorter.

- Maintenance: Most floor sealant options offer years of protection as long as they’re maintained. Most companies offer a two-year warranty on epoxy. At BlackHawk Garage Door, we offer a 15-year warranty on polyurea for residential properties.

Contact BlackHawk Garage Door Today for Garage Floor Sealing

If you want to install a new protective coating for your garage floor or repair your existing coating, we’re here to help. BlackHawk Garage Door is a family-owned business that has years of experience in the business, and our team can help you decide on the best garage floor protection.

If you’re located in Minnesota or western Wisconsin, contact us today to schedule garage floor services!

Concrete Floor Coating Guide: 10 Uses of Polyurea Flooring

There’s a new name to look for if you’re searching for floor coatings that offer durability, longevity, waterproofing and easy application — polyurea floor coating. In many areas, this coating surpasses the popular epoxy flooring often used in home garages. You will find innumerable uses beyond your garage for applying polyurea flooring.

What’s the Difference Between Epoxy Flooring and Polyurea Floor Coatings?

For starters, both applications can cover concrete, hiding years of wear and tear. But that’s where their similarities come to an end. The two concrete coating options differ significantly in visual appeal, UV stability, durable functionality, moisture barriers, slip resistance and lifespan.

Visual Appeal

Epoxy and polyurea applications can enhance your garage, basement or patio. Epoxy can cover superficial flaws, but it is not a superior way to even out cracked, chipped or dangerously uneven surfaces. The polyurea chip system allows homeowners various options to choose a color that will match the rest of their interior or exterior decor.

UV Stability

Polyurea concrete floor coatings have UV-stable elements that will not fade or yellow with exposure to the sun. Epoxy cannot withstand UV damage and will become discolored over time.

Durability

Salts, chemicals, oils and temperature changes can significantly damage your garage door over time. Polyurea concrete floor coatings are among the most durable flooring choices. Proven to be nearly five times stronger than epoxy, polyurea can withstand heavy traffic, skids, abrasions and impacts. Polyurea concrete floor coatings also offer an impenetrable barrier against moisture and unwanted pests where epoxy does not.

Polyurea is impervious to damage, accidents and mishaps for over a decade, whereas epoxy will protect the flooring from salts and chemicals, but only for a short time.

Unlike polyurea concrete floor coating, epoxy provides less-than-ideal temperature change protection. The material lacks the elasticity to move with your home’s foundation when it expands and contracts. That means it will crack and pop over time in response to temperature changes. Polyurea will expand and contract with your concrete and has proven to be 98% more flexible than epoxy. People who depend on epoxy to withstand Minnesota and Wisconsin winters will encounter pitting, chipping and splitting within a few years.

Moisture Barrier

If your garage floor has a high moisture content, moisture vapor transmission from underneath the slab can delaminate the coating. BlackHawk Garage Door will always bring a moisture reader to your property to determine whether you have a moisture issue. If so, our polyurea floor coating can help.

Slip Resistance

We know epoxy is a non-porous product that creates a smooth surface. However, this can pose a threat when epoxy floors get wet and become slippery, especially with oil spills. With the polyurea chip system, the floor becomes slip-resistant. Ask about the various resistance levels BlackHawk Garage Door offers.

Lifespan

Polyurea is highly elastic (300%) and will accommodate expansion, contraction and relative movement within concrete without cracking. It has a service history that exceeds 25 years. Epoxy is a thermosetting resin that coats the floor, but doesn’t withstand the elasticity you need as your foundation settles. Minnesota and Wisconsin experience harsh winters, and epoxy floors experience pitting, chipping and splitting. Polyurea coatings receive high marks from homeowners and businesses for this reason, in addition to being stain-resistant, UV-stable and antibacterial.

Residential Uses of Polyurea Coatings

Thanks to polyurea’s durability and longevity, you will find many flooring uses that don’t include a surface to park cars on. While most people think of this option as a garage floor coating, there are many more places where you can have us install this flooring.

Garage Floor Coating

Of course, most people think of polyurea coatings for uses of garage flooring. While an epoxy floor may sustain damage from parking your vehicle with hot tires on it, a polyurea-coated garage floor will not. This type of floor can also hold up to the temperature and moisture extremes homeowners experience in our service areas of Wisconsin and Minnesota.

Home Gym Flooring

Because polyurea can stand up to impacts and have the option for varying levels of slip resistance, they are ideal for flooring in home gyms. In such locations, you need a floor that can hold heavy weights or machines, plus resist cracking or chipping if you drop a weight on the floor. Whether you have multiple workout machines or a single treadmill and set of free weights, polyurea flooring will offer the lasting performance you need.

Laundry Room Floor Coating

Laundry rooms require a durable surface that can stand up to moisture, humidity and temperature changes. For instance, when you run a clothes dryer, the room will heat and the humidity will rise. You also need a surface that offers slip resistance in case water from wet clothes gets on the floor. Polyurea flooring is the solution to these needs.

Workshop Floor Coating

In a workshop, polyurea will suffice for most applications. The only possible concern you might have is when you weld materials over the coating. While polyurea coating can stand up to heat, it may burn from welding’s excessive temperatures. Otherwise, as a workshop floor coating, polyurea will help reduce dust that might accumulate on a bare concrete floor and offer a slip-resistant surface, improving the area’s safety.

Finished Basement Flooring

For finished basements, you want flooring that is durable and easy to clean. Polyurea requires only spot cleaning to remove spills. However, with its stain resistance, you don’t need to worry about a spilled drink in your basement rec room causing a permanent problem. Dust mops suffice for removing any dust from the surface, and you can use a sponge mop for regular cleaning of heavily trafficked areas.

Outdoor Pool Areas

Epoxy floor coatings won’t stand up to the moisture, UV rays and temperature swings that an outdoor pool area would experience. Therefore, you need a durable surface coating like polyurea. Plus, you can choose various slip resistance levels for your surface. Around a pool, you want the maximum possible slip resistance to make the area safe for everyone.

Commercial Applications for Polyurea Flooring

Homes are not the only places where polyurea flooring has uses. Businesses in all industries made this floor coating their surface of choice long before consumers discovered its benefits. From auto shops to hospitals, many businesses can take advantage of this surface’s durability and long life with a faster application time than epoxy.

Auto Shop Flooring

Auto shops require tough flooring that can resist damage from hot tires, dropped tools and stains. Polyurea floor coatings excel in these requirements where epoxy floors would not. Additionally, with one-day installation, your business won’t need to delay operations long when you have polyurea installed.

Warehouses

Warehouses have heavy vehicular and foot traffic, plus weight from the shelves and stored products. Workers cannot risk slipping and falling in such a busy location. You need polyurea’s slip resistance that can also hold up for years.

Car Dealership Showrooms

Car dealership showrooms have unique needs. First, the flooring needs to hold up to customers walking over it daily. Additionally, the floor cannot experience stains or wear from vehicles driven over it as you pull model cars into their display locations. Lastly, the floor must look good and hold up for a long time. Polyurea flooring has many color and chip options to customize your space’s appearance.

Hospitals

The floors in hospitals undergo heavy traffic, but they must also be easy to sanitize. Polyurea flooring is antibacterial, preventing viral spread and allowing for quick sanitation. It also protects people walking on the surface from slipping. In a hospital setting, durability and ease of cleaning are essential attributes of any floor coating.

Contact BlackHawk Garage Door for Polyurea Flooring

With our one-day installation in most commercial and residential locations, you can begin to enjoy your new flooring much sooner than if you had epoxy installed. Find out more about our polyurea flooring on our site, or contact us at BlackHawk Garage Door for questions or to request an appointment. Our professional technicians are ready to help you get better flooring for your garage, gym, workshop or any other space where you need polyurea floor coating’s extra benefits.